Hydrolyzed Protein and Manufacturing Methods

Last October, American food professionals visited fermented food producers to deepen their knowledge of Japanese fermentation culture during the “Hakko Tourism in Japan” tour campaign. As part of the tour, organizers held a tasting session where guests gave candid advice from the perspective of the American market to food product manufacturers looking to enter the United States market.

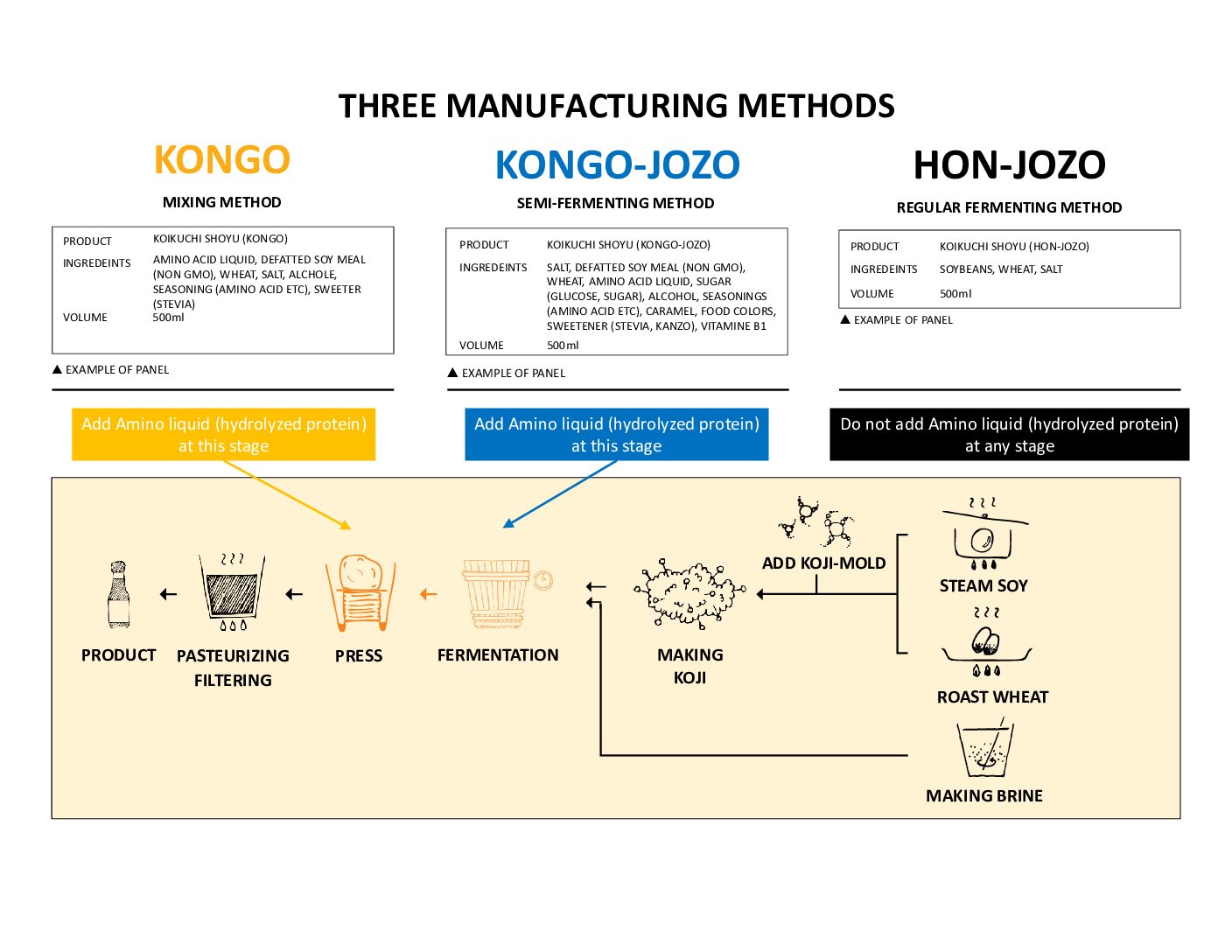

Three manufacturing methods: hon-jozo, kongo, and kongo-jozo

“Hon-jozo” does not necessarily mean “additive-free.” Ultimately it is only a soy sauce that does not contain “hydrolyzed protein,” and some hon-jozo contains various ingredients such as amino acids and sweeteners. Brewing methods and ingredients are indicated on the label and learning how to read labels can help you to buy the soy sauce of your choice.

What is amino acid liquid anyway?

History of adding amino liquid to soy sauce

Keiko Kuroshima, the world's first soy sauce sommelier and certified sensory inspector, hails from Japan's soy sauce production hub in Shodoshima. She co-authored a book on the island's breweries and is the only female among the three soy sauce sommeliers worldwide. Her expertise and passion elevate soy sauce appreciation globally.