Top 3 Containers for Making Koike

Last October, American food professionals visited fermented food producers to deepen their knowledge of Japanese fermentation culture during the “Hakko Tourism in Japan” tour campaign. As part of the tour, organizers held a tasting session where guests gave candid advice from the perspective of the American market to food product manufacturers looking to enter the United States market.

Soy sauce can be made with any container as long as liquid does not overflow.

We will be looking at different types of containers to make soy sauce such as kioke, wooden barrels, and large stainless steel covered outdoor tanks where most of the soy sauce is brewed today. Other types of containers range from earthenware used to make hishio, the forerunner of soy sauce in the Yayoi period, to plastic bottles used today to make homemade soy sauce at home. So what difference does using different containers make? This time, we will take a closer look at the characteristics of each type of brewing containers.

Key historical changes in brewing containers

Let’s get a feel for the characteristics of the main types of brewing containers.

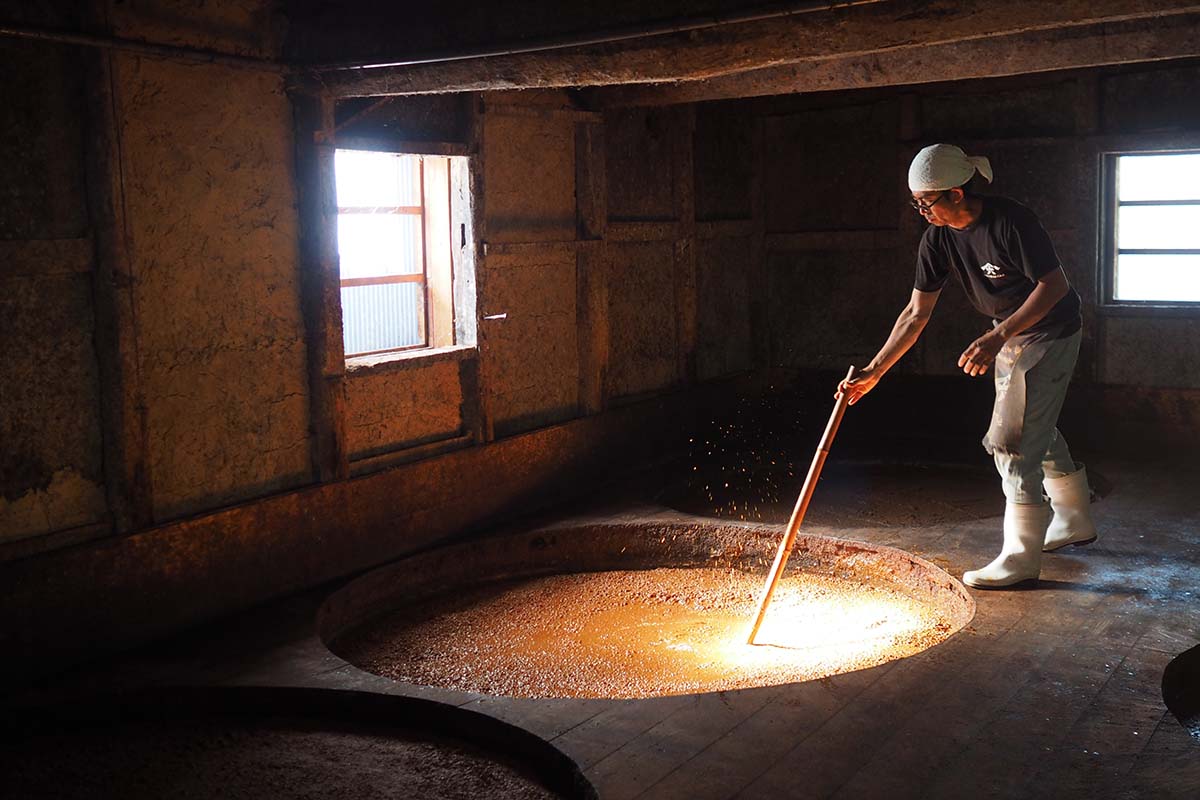

Kioke, the mainstream in the Edo period (1603 – 1867)

Earthenware and jars used before kioke were heavy and limited in size, but with the advancement of technology, large containers (kioke) started to be used during the Edo period. They are made mainly of cedar wood, which allows mold to live in the gaps between the wood fibers and are relatively easy to repair.

Concrete tanks, popular containers from the early Showa era (1926‐1989)

Some concrete tanks are as wide as a swimming pool and as deep as three meters. Small to medium-sized soy sauce manufacturers started to actively implement concrete tanks around 1920 which were relatively inexpensive and more space-efficient due to the shape of the tank compared the round shaped kiokes. However, due to the difficulties in repairing them when corroded by salt, they have not been as popular in recent years.

FRP tanks, popular containers from the late Showa era

FRP (fiberglass reinforced plastic) tanks are plastic tanks that have been reinforced with fiberglass. It has excellent weather, heat and chemical resistance, is lightweight, can be designed into various shapes, and is low cost. Because of these advantages, they are still one of the most popular choices for small breweries today.

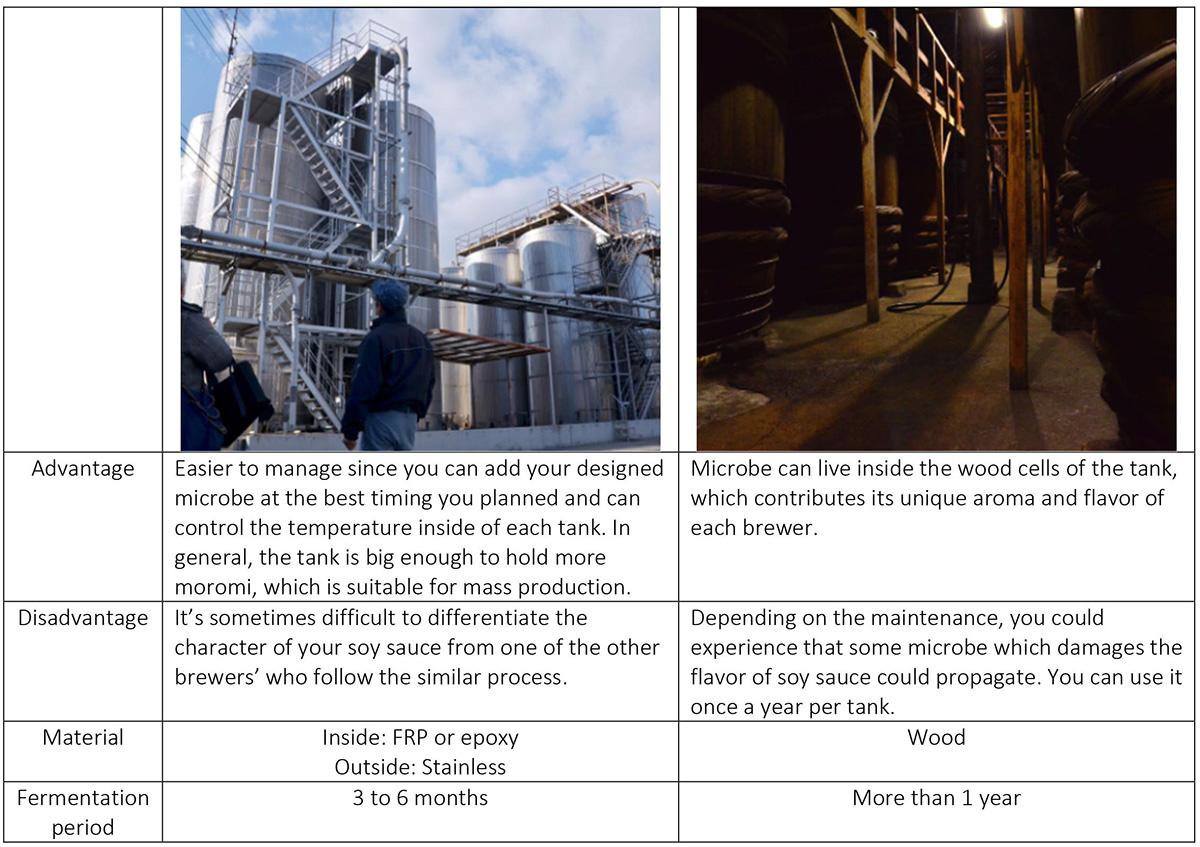

Large outdoor fermentation tanks, popular containers from the late Showa era

The inside of the tank is made of FRP or coated with epoxy resin, and the outside is made of stainless steel. With heating and cooling equipments placed between tanks, heating and cooling moromi in each tank can be easily controlled for quick brewing. Outdoor tanks do not require a building and can be expanded to a larger size for mass-production. For these reasons, they are the top choice of high production manufacturers.

Brewing with naturally inhabiting mold or artificially cultivated optimized mold?

The key point is that kioke and concrete tanks can brew using naturally inhabiting mold, whereas FRP and outdoor large fermentation tanks can be cleaned and made mold-free, and brew using artificially cultured optimized mold.

Kioke is a mass of wood fibers, a space in which microorganisms can easily live. The microorganisms that live in kioke change depending on the natural environment and how it is managed, and creates a unique ecosystem that gives each brewery its own unique soy sauce taste and aroma, making it easy for each brewery to demonstrate its own characteristics. On the other hand, there are countless microorganisms living in soy sauce cellars. If nuisance microbes become dominant affecting the taste of the soy sauce, there is a risk that the ecosystem will be difficult to reset, and so the brewers need to pay more attention to the nuisance microbes than to the ones that produce good flavors. Even in the same brewery, there are always good barrels and not-so-good barrels.

Large outdoor fermentation tanks and FRP tanks are cleaned before brewing to make them nearly mold-free. After new moromi is made, the optimized mold is added to the pure culture at the optimal timing, so it is easy to produce soy sauce of the same quality consistently. Even if there are microorganisms that interfere with the process, it is easy to reset the process. On the other hand, the reality is that many breweries find it difficult to create their own unique characteristics.

Soy sauce made in tanks are consistent but average in quality, whereas soy sauce made in kioke can be better or worse than average in quality depending on the management level. There are both pros and cons in using either kioke or large outdoor fermentation tanks, and hard to simply conclude that one is better than the other.

Keiko Kuroshima, the world's first soy sauce sommelier and certified sensory inspector, hails from Japan's soy sauce production hub in Shodoshima. She co-authored a book on the island's breweries and is the only female among the three soy sauce sommeliers worldwide. Her expertise and passion elevate soy sauce appreciation globally.