Kioke: Materials Used for Kioke

Last October, American food professionals visited fermented food producers to deepen their knowledge of Japanese fermentation culture during the “Hakko Tourism in Japan” tour campaign. As part of the tour, organizers held a tasting session where guests gave candid advice from the perspective of the American market to food product manufacturers looking to enter the United States market.

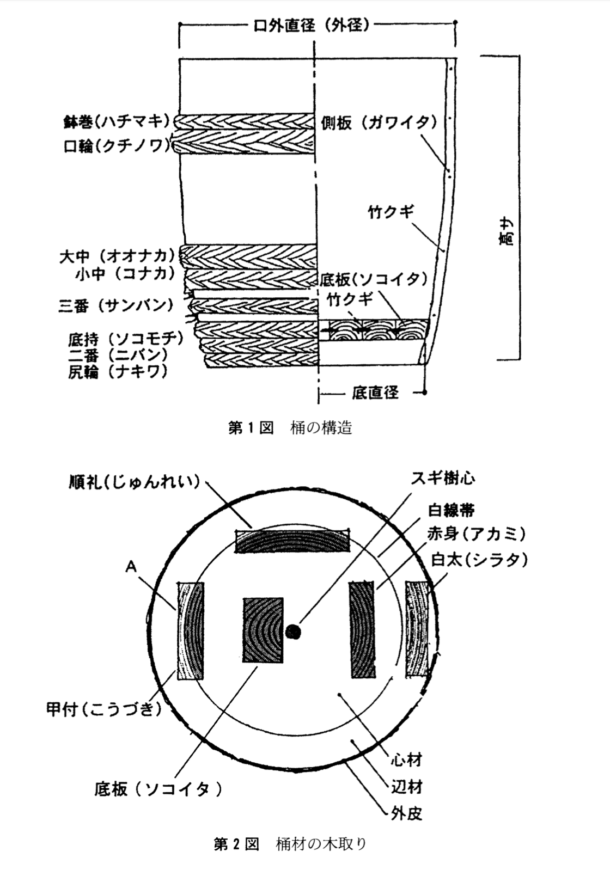

Kiokes are made solely from Japanese cedar and bamboo. It is not only the skill of the barrel craftsmen, but also the high-quality cedar and bamboo that make it an excellent brewing vessel that is taller than a human being, does not leak even when filled with liquids with high osmotic pressure, can be used for over 100 years if made well, and is easy to repair and recycle. So how are the materials selected? Let me take you on a tour of the esoteric world of wood.

Selecting cedar wood is like a treasure hunt

The parts used for the sides and bottom of the container are made of cedar. The cedar staves are connected to each other by “bamboo nails” made of shaved bamboo. Cedar is used because it is a wood with little harsh taste or woody smell and is easy to process. Cedar is planted in many parts of Japan, but Yoshino cedar, grown in central and southern Nara Prefecture is most suited for use in wooden vats. Because they are densely planted, Yoshino cedar has dense annual rings and produces wood with few knots.

If sake is brewed in wood with knots or splits along growth rings, bacteria such as lactic acid “hiochi” bacteria that cause spoilage of sake can grow in the gaps and degrade its flavor, so knotless, tight-grained wood is necessary. Of these types of wood, the sides of sake barrels are made of “kozuki (parts that contain both sapwood and heartwood),” which have a “white zone” that is a woody layer that prevents the dissipation of alcohol and other substances. To convert timber as shown in the figure, only four pieces of this precious wood can be obtained from any one log, no matter how thick it is. The bottom heads use the heartwood close to the core.

The outside is white across the “white zone” and the inside is red. Inner heartwood is considered better for preserving sake because it is paler with less resin, so it is used with the heartwood facing the inside, and the bottom head is made of heartwood as well.

The closer to the core, the more knots there are, so very few pieces of wood can be used for the bottom heads. In addition, during the long period of 100 years or so that the tree grows, “water cracks” form where some of the fibers of the tree shaken by storms split, and small “dead knots” also form where dead branches grow up and die off. Some trees are affected by lightning strikes, although not apparent, which may have shattered parts of the middle section. Finding the right wood is a treasure hunt in itself, as one looks for weaknesses that lie deep beneath the bark.

– Ueshiba, T., 2011. Shikumioke no rekishi to tenkai. Journal of the Brewing Society of Japan. Vol 98.

– Kato, K., 2003. Okeya no Chosen. Chuo Koron Shinsya.

The best material for hoops is long and straight madake bamboo (Phyllostachys bambusoides)

Not just any bamboo will do. Madake bamboo must be used. It is suitable for weaving hoops because of its low knots and long internodes, as well as its elasticity. In addition to the need to be straight, the madake bamboo must be at least 13 meters long to weave a hoop for a 20-koku (= 953 gal = 3607 L) barrel, and 18 to weave a hoop for a 30-koku (=1430 gal = 5212 L) barrel.

On the other hand, bamboo forests must be meticulously cared for or the bamboo will not grow to be long and straight. In the past, the labor was divided between craftsmen who grew the bamboo and craftsmen who split and shaved it, but with the decrease in demand for vats, the bamboo craftsmen have disappeared, and now the vat craftsmen do everything from finding the suitable bamboo to making the vats. Consequently, the maintenance of bamboo is out of our reach and the current situation is that there are very few straight and long madake bamboo available that is optimal for kioke.

While it seems impossible, miraculously the best bamboo is found and cut from a bamboo grove during the cooler months of the year when insects are less likely to penetrate it. It is immediately split and shaved to preserve it, and then woven into a hoop when the vat is assembled. The bamboo is not only used for weaving, but is also processed into the “core” that goes inside the hoop and the bamboo nails that connect the staves to each other.

Keiko Kuroshima, the world's first soy sauce sommelier and certified sensory inspector, hails from Japan's soy sauce production hub in Shodoshima. She co-authored a book on the island's breweries and is the only female among the three soy sauce sommeliers worldwide. Her expertise and passion elevate soy sauce appreciation globally.